Listing ID #3522638

Company Information

Ask for more detail from the seller

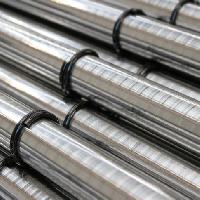

Contact SupplierPeeling is Removal of outer surface of Bars by means of Rotating tool. Surface defects are deeper and proportional to the diameter of Bars, Removal of such defects is done by peeling where in a cut is given as per Requirement. Peeling leaves minor turning marks on the surface so often customers prefer to have peeled bars and if customer requires Peeled Bars without Tool marks then it needs to be Grinded through Center less Grinders.