Company Information

Ask for more detail from the seller

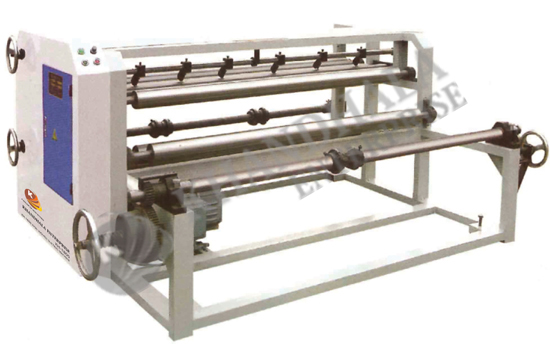

Contact SupplierKnown for its noise-free operation and energy efficient design, the offered Paper Cup Making Machines are highly demanded in the market. For the purpose of manufacturing best quality paper cups, the offered paper cup making machines are highly demanded in various industrial applications. These machines are rigorously checked on quality assurance parameters to ensure a defect free range.

Features :

Paper Cup Manufacturing Process :

Single side PE coated paper is loaded to the printing press to reproduce the desired image on the paper Printed PE Coated paper is then cut and punched in the die cutting machine according to the size requirements Then the cup forming machine process starts, which is detailed as below :

Cup Forming Process :

Blanks after printing and die-cut are feed in pre-cut cup-fan-shape sheet PE-paper to the entrance of the paper cup machine