Company Information

Ask for more detail from the seller

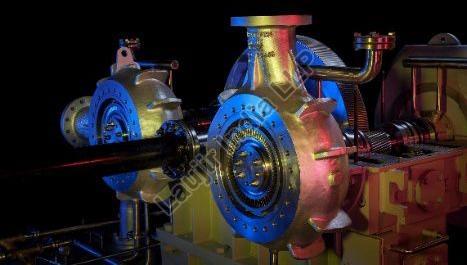

Contact SupplierOverhung Design Condensing and Back Pressure Steam Turbines

Overhung Design Turbine system is designed to conserve unutilized pressure energy in a Process Plant, specifically by utilizing PRV/PRDS (Pressure Reducing Valve/Pressure Reducing Desuperheater) systems that would otherwise simply throttle excess steam pressure. The ECT reduces steam pressure to the required process (back) pressure while converting the pressure energy into high velocity to rotate the turbine wheel at a speed of 12000 RPM. This high-speed rotation is then reduced through a reduction gearbox to 1500/3000 RPM to generate incidental clean, green electric power.

Key Features:

1. Versatile Steam Utilization:The ECT system can utilize saturated steam, making it highly beneficial for industries using saturated steam for various processes.

2. Turbine Frames:The system is available in different frames to accommodate varying power requirements: Frame A (up to 250 KW), Frame 2 (251 to 750 KW), and Frame 3 (751 to 3500 KW).

3. Turbine Highlights:Stainless steel construction of all steam-wetted parts ensures long corrosion-free life.Precision CNC milled aerodynamic blading maximizes turbine efficiency.The turbine is machined from a solid hardened stainless steel forging for maximum durability.Hardened and ground precision helical gears ensure long-life and smooth operation.The unit is designed for low noise and high efficiency, with a unitary skid for all equipment, providing a single compact and factory-assembled unit.The system is fully automated, requiring no dedicated operator, and includes redundant in-built safety features for reliability and safety.The system offers industries a cost-effective and environmentally friendly solution for harnessing excess steam pressure to generate clean electric power, contributing to energy conservation and sustainability initiatives.