Listing ID #4082677

Company Information

Ask for more detail from the seller

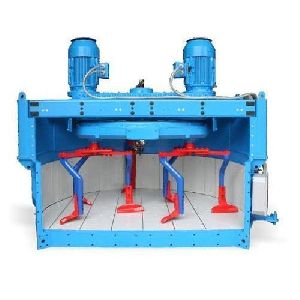

Contact SupplierFor Ointment - Cream - Lotion - Paste etc. Manufacturing

With Double Stirrer, Scrapper & Centrally Located High Speed Emulsifier

• Range of models to suit gross volume 60, 100, 140, 200, 350, 600, 1000, 1500 & 2500 Liters for OINTMENT - CREAM - LOTION - PASTE - TOOTH PASTE.

• All contact parts are made out of S.S.304 quality material. (SS316 provided on demand on extra cost)

• Compact design requires comparatively smaller floor space.

• Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 2500 liters size models. (In 60 & 100 liters models product container moving up & down manually. Motorised system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system.

• Castore wheel mounted product container for the ease of mobility. (This facility available from 60 liters to 350 liters model only.)

• Container with fixed legs above 350 Liters model. Hence no facility of mobility of container.

• A high-speed emulsifier (Homoginizer) will be provided at the center axis, in 140 liters model and above capacity model only. (It can be interchangeable with disperser & necessary assembly provided with m/c)

• In-Line Homoginizer also provided on demand, if required.

• Double stirrer & SS scraper with PTFE blades for better mixing of the material. ( In 140 Liters & above model only )

• Single stirrer with scrapper in 60 & 100 Liters model.

• Planetory motion of the stirrer ( beaters ) enables faster and better mixing of the material at a considerable lesser time.

• As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem.

• Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 60 to 350 liters model. Steam heating recommended in 600 litres to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.)

• All non contact parts (general structure) made out of mild steel and claded with SS304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model.

• General structure & all non contact parts are made out of Mild Steel & same wil painted in Standard Model.

• Fixed type product container in 600 litres and above capacity models.

• Heater with temperature controller for heating facility. (For 60 / 100 / 200 / 350 litres OINTMENT MIXER only)

• 100 % utilisation of machine can be possible due to facility of change of extra product container.

(In 60 to 350 litres model only)

• Vacuum facility provided on demand for de airation during mixing in Gel product. (For OINTMENT MIXER only)

• Insulation will be provided on jacket of container. (For OINTMENT MIXER only ) as a optional facility.

• Material discharge from bottom. Flush bottom valve provided for material discharge in 350 litres

and above model only. (For OINTMENT MIXER only)

• M/C provided with Light glass, Sight glass , material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only)

• All connection of valve, light glass, sight glass will be triclover ended.

• Sampling port provided in 600 litres & above model.

• Flush bottom type valve in 600 litres & above model.

• All moving parts are enclosed with safety guards.

• SS316 product contact parts instead of SS304.

• Vacuum system for deairation during mixing. (For gel products)

• Variable speed drive for main agitators motor and emulsifier motor.

• Vacuum Pump Set.

• Flameproof model.

• "PLC" based operating panel for automation.

• Hydraulic lifting system in 60 to 200 litres model, instead of mechanical lifting system.

Ideal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colours and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc.