Listing ID #4057406

Company Information

Ask for more detail from the seller

Contact Supplier|

The Problems:

Problem of Oil / Grease Pollution in Effluent: Oil Pollution in effluent, oil - grease contamination is mainly caused due to Washing / Cleaning of Mill/ Machineries in Plant. The escaped Oil & Grease to ETP crosses the maximum permissible limit in the final effluent. Its protective layer in the effluent channel inhibits the exposure of biodegradable effluents to the atmosphere. As a result, the BOD of incoming effluent to ETP is also more than desirable incurring additional cost of aeration. Often, the ETP aeration system in the majority of mills / industries does not operate as desired. Consequently the effluents leaving the factory invariably contains higher ppm of oil and BOD levels higher than permissible. The problem is more serious for the mills, where the effluent/ water is used either for irrigation purpose or discharged in the inland rivers. |

|||||||||||||||||

|

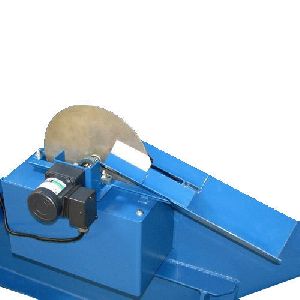

I) Oil Skimmer, the Best Solution: To Solve this problem of Oil Pollution right at the source of contamination, we have designed & successfully commissioned Oil Skimmers with especial designed oil catch pits in effluent channel. This method, while controlling the pollution also enables the factory to reuse the recovered Oil, for general lubrication purposes like conveyors rollers; guides; press plates; chain / sprocket gears and weather proofing of spares and also as fuel for boiler firing. More than 100 Factories have installed Oil Skimmers in India. The cost of installation as a result of saving in oil consumption due to recovered oil in 100 days is paid out and at the same time brought down the ppm level below the limits set by CPCB Norms.

|

|||||||||||||||||