Listing ID #1788543

Company Information

Ask for more detail from the seller

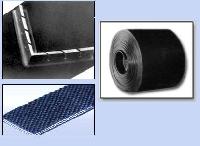

Contact SupplierWe offer oil and grease resistant conveyor belts specifically designed to convey different types of materials that contain any kind of oil and fat, it will not effected by paraffin oil, naphthene oil, gasoline animal or vegetable fats, etc.

Conveyor Belts are used to Convey Different types of Raw materials, The Raw Materials which contains Oil & Fat, Like Poultry Feed, Fish Feed, Soybean Draff, Packed Fish, Meat Products etc , damage the belt and penetrates Oil and Fat into the rubber causing it to swell and distort, resulting in lack of performance life of the belt and serious operational problems.

We offer oil and grease resistant conveyor belts specifically designed to convey different types of materials that contain any kind of oil and fat, it will not effected by paraffin oil, naphthene oil, gasoline animal or vegetable fats, etc.

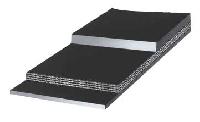

These Belts are specially constructed with Nit rile Butadiene Rubber (NBR) with Polymer that is resistant to oil and grease and provides higher performance life of the Conveyor Belt.

These Belts are made of cotton, nylon and EP Fabric finished through the processes of calendering, assembling, vulcanizing , These belts are widely used in various industries such as the chemical and fertilizer industry, wood, paper and pulp, sugar and food, transshipment and recycling plants.��

We offer two types of oil-resistant rubber conveyor belt

1) Oil and Fat resistant Rubber Conveyor Belt – for products which contains paraffin oil, naphthene-based oils, petrol animal or vegetable fats etc ,These belts are mostly used in Soybean draff , Fish meat , concrete and Batching plants , Mineral processing plants, waste sorting and compost machine ,Timber industry and sawmills, paper and Corn Industry ,Solvent Extractions Plants.

2) Oil and Heat resistant Rubber Conveyor belt /Elevator Belt- for products which contain oils and heat – Like Soya been Plants to Carry DOC ,Bitumen plants , Hot Mix Plants , We offer Heat & Oil Resistance up to Temperature of 180 C