Listing ID #3943928

Company Information

Ask for more detail from the seller

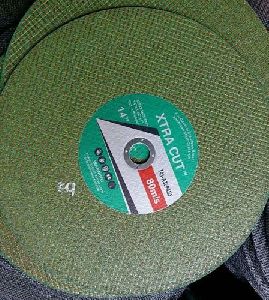

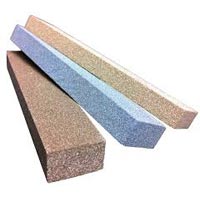

Contact SupplierOffhand grinding wheels are used in bench, pedestal and portable grinders to remove excess material, sharpen tools and in the smoothening of weld seams.

Noble offhand grinding wheels are made to reduce operator fatigue, last long and grind a wide variety of materials while reducing overall grinding costs. They find use in the grinding of excess material found in large castings and forgings, smoothening of weld seams and re-sharpening of single point cutting tools. Our wheels are made of brown aluminum oxide (to grind steel and steel alloys) and black silicon carbide (to grind non-steel and non-ferrous materials). Offhand grinding wheels can be used on portable grinding machines as well as bench and pedestal machines. Some of the major industries that use offhand grinding applications are

Standard Sizes