Listing ID #1393225

Company Information

Ask for more detail from the seller

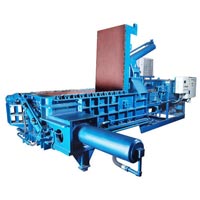

Contact SupplierWe offer high grade Numerical Control Hydraulic Press Brake that is ideal to be used for multiple bend jobs. The Numerical Control Hydraulic Press Brake that we offer is high in strength and is fabricated using superior quality material. Also, we are one of the reliable Manufacturers, Exporters, & Suppliers of Numerical Control Hydraulic Press Brake.

Preferred For :