Company Information

Ask for more detail from the seller

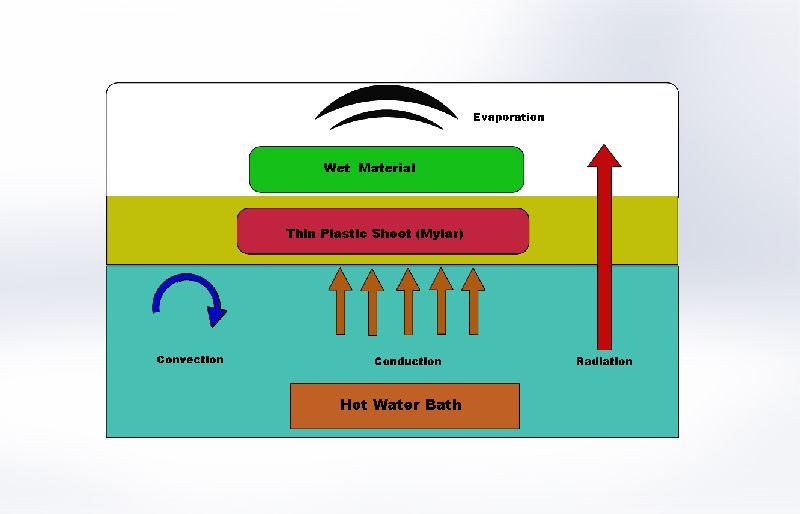

Contact SupplierNovel Refractance Film Drying uses low temp. and short-time continuous process to dry delicate, heat-sensitive products. Drying takes place at atmospheric pressure to retain product color, flavour, aroma and nutritional content. Product quality is comparable to and, in some instances, better than that achieved by freeze-drying. This is done at significantly less capital and energy cost

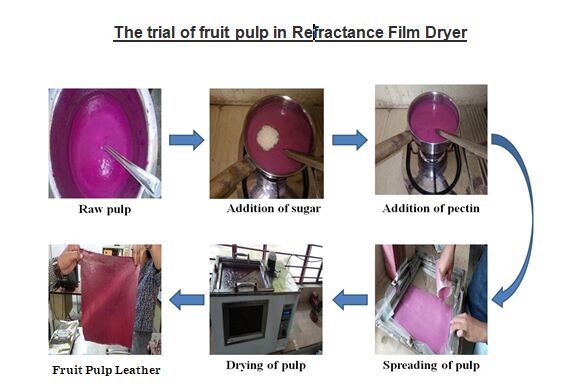

Our Novel Refractance Film Dryer are suitable for Fruit and vegetables purees, Single Strength Purees, Concentrated purees, Chunky purees, Fruit & Vegetable Leather, Juices, Seed Pulp, Sliced Fruits and Vegetables, Meat and poultry purees and Broths, Fish- Purees and Broths, Egg Products Egg Powder, Dairy Products including Dairy Cultures, Cereals, Grains and Starches, Beverages- Concentrates and Mixes, Nutraceuticals-Proteins Powder, Pharmaceuticals, Algae, Fine Chemicals.

Advantages

• SuperiorFoodQuality

• LongerShelfLife

• LowerOperationCosts

• NoCross-ContaminationOccurs

• ShorterDryingTime

• Requires50-70%LessCapital

• 50%LessEnergythantheFreezer Drier