Listing ID #3017258

Company Information

Ask for more detail from the seller

Contact Supplier1. Technique introduction

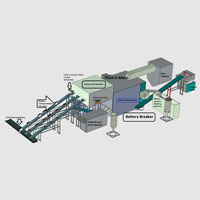

it is an integrative equipment for lead acid batteries grinding and metal and non-metal separation. At first batteries are grinding and collect acid water by automatic machine. Then scrap batteries go to grinding and separation equipment. Finally metal and plastic can be obtained. This equipment has been combined the most advanced grinding and separation techniques in the world and adopted unique process technique. It works in enclosed environment and no waste water, drogs and poisonous gas give off during production.

2. Technical specifications of lead acid battery recycling plant:

car battery recycling production line

factory size (l*w*h): 40m*20m*10m

dimension (l*w*h): 25.8m*10m*4.5m

capacity: 1-5th

total power: 280kwplant

granularity of metal (mm) 2-40mm

metal recovery rate: 97%-99%

granularity of non-metal (mm) 2-40mm

operators: 3 worker

raw material: waste lead-acid battery

output product: acid, lead paste, plastic, lead grids.

Electricity standard: 220-480v, 5060hz (tailor made)

3. Environmental protection standards

a. Emitted exhaust gas consists with secondary standard of “emission standard of air pollutant” (gb16297-1996)

b. The equipment uses negative pressure transportation, no dust in operation environment. Slight dust leak in the outlet can be manually controlled.

4. Characteristics and benefits

a. The coarse crush can grind batteries and collect acid water

b. National environment protection standard achieved. No dust leak and no secondary pollution such as waste water and exhaust gas.

C. Low energy consumption but high production.

D. High metal recovery rate which reaches 96%-98%. Metal content in non-metal powder is less than 1%.