Listing ID #4215468

Company Information

Ask for more detail from the seller

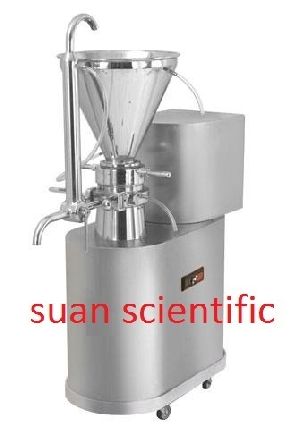

Contact Supplier‘acme’ colloid mill is very suitable for homogenizing, mixing, emulsifying, dispersing and comminuting of liquids to highly viscous products. the rotor-stator principle is used for that. for the heat sensitive products the plain and water jacketed model is very suitable. on demand the flame proof electrical can be supplied.

how to operate :

there is a rotor having the speed of 3000 rpm by specially designed feed device. the product is placed to the rotor. the product is processed by the stator and rotor. the stator and rotor do it by shear, pressure and friction. it is also subjected to intense vibrations. it exerts the force by pressing and releasing actions, because of the deviating tapering of the milling surfaces of stator and rotor. the processed products continuously leave the mill through the drain pipe. it can be recalculated if required.

which features make it better :