Listing ID #4387508

Company Information

Ask for more detail from the seller

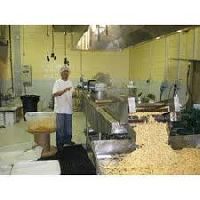

Contact SupplierFarsan And Namkeen Plants

1. KNEADING Raw materials are mixed in the desired proportion in the kneader. The kneader ensures good mixing of the ingredients and forms a dough. The texture and composition of the dough depends on the mix of the raw materials used.

2. EXTRUDING The dough is fed to the extruder hopper. A screw from the bottom of the hopper conveys the dough to the extruder head.

The extruder head can be fitted with a mesh of desired hole size and shape. Thismesh determines the size and shape of the end fried product. The dough isextruded from the extruder in the desired shape into the fryer.

3. FRYING The output from the extruder is fed to the fryer. The fryer consists of a longvessel in which a conveyor is placed to convey the product. The vessel has hotoil in which the product is fried. The hot oil is filtered and circulated in thesystem. An edible oil heater heats the oil up to the desired frying temperature.The edible oil heater is a direct fired unit with the burner operating on diesel asfuel. The oil circulation pump and the burner operate to maintain thetemperature of the oil at the set frying temperature. The burner is automaticand works ON – OFF based on the input of the temperature indicator andcontroller.The product fed from the extruder to the fryer travels through the bed of hot oiland is cooked and discharged from the other end. The cooking/frying time andthe temperature are variable and can be set according to the product being fried.Thus the product quality as desired can be obtained.The system has a used oil storage tank with a cooling water jacket. The hot oilleft in the system after the production cycle can be pumped into the tank. Withthe cooling water circuit on the hot oil is cooled for overnight storage. This oil isused as make up oil during the next days production cycle. An automatic levelmake up system ensures that the oil level in the frying vessel is maintained tothe desired point. This ensures the consistency and the quality of the friedproduct.

The complete system contact parts are in stainless steel SS 304 exceptingstandard components like bearings, housings, etc. all standard components likemotors, switchgear, controllers, bearings, etc. ensure that the system operatessmoothly and there is easy availability of spares. A control panel with starters and controllers is provided for the smoothoperation and control of the plant.