Listing ID #3665257

Company Information

Ask for more detail from the seller

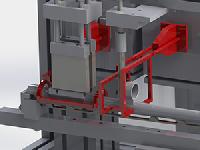

Contact SupplierMulti-Head Spot Welder

Multi-Head Spot Welding Machine is specially designed for welding floor tiles fabricated assemblies. The machine is equipped with ten welding heads, five welding transformers, microprocessor based control, pneumatically actuated welding heads and job guides.

Operation:

The operated loads the pre-tacked assembly on the welding machine and position the job for the first set of spots on flange. He then initiates the welding heads descend to weld and retract after welding,. The operated then indexes the job forward to align with the next set of spots to be made. This sequence is repeated till all the spots are made. The determines the welding heads, which are actuated in three groups.

The ten welding heads are divided into three groups. The middle six heads are in one group. The two outer heads (first from each end) are in one group and the immediate next heads are in group. A selector switch(s) determine which heads are actuated when the foot-switch is initiated. This permits selected group from being activated when the corresponding spots are not required.

Construction:

The main frame of the machine is “D” frame type and is of heavy, rigidly reinforced welded steel construction. The welding heads are on the upper arm. The lower arm provides the reaction force required and the bottom shunt or electrode. The machine frame combines a compact streamlined appearance with maximum resistance to mechanical deflection. The transformers are housed inside the machine frame. The control is either mounted on the machine frame or free standing and easily accessible.

Welder Control:

PLC based welder control, with logic and sequence control, complete with thyristor contactor is provided. The welding parameters are settable and can be easily adjusted to suit requirement. The control has fault annunciation capability.

Cooling systems:

The transformers, electrodes and thyristors are water cooled and provided with inlet manifold and outlet manifold. Alternately, the discharge to an open drain pot, for visual observation of flow, can be provided.

Electrode Control System:

Heavy–duty pneumatic cylinders actuate the electrodes. The cylinders are operated through solenoid valves by the weld control. Compressed air at 2 kg/cm2 to 7 kg/cm2 acting through the pneumatic cylinders provides the electrode force. Machine is provided with air filters, regulators with gauge, lubricator etc, together with internal air connections.

Adjustments of Welding Force:

The welding force is adjusted by setting the air pressure in the welding head cylinder wit the help of the regulators.