Listing ID #1640452

Company Information

Ask for more detail from the seller

Contact Supplier|

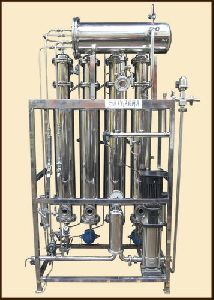

J.K.INDUSTRIES Multi Column Distillation Plant is based on FINN-AQUA design. It consist of specially designed columns which make optimum use of the principles of interstage heat exchange (Multi effect distillation method) to produce pure pyrogen free sterile distilled water for injectables as per IP/BP specification. The vapour with high velocity and under pressure passes over a SPECIALLY DESIGNED SPIRAL BAFFLE system which develops tremendous centrifugal force and thus eliminates any chances of pyrogens carry over in the vapours. |

|

|

Operation : |

|

|

The pre-heated feed water (through condensor) is fed into the first column where 33% of feed water is converted into steam under pressure by outside boiler steam. The pure steam produced in the first column having temperature of 135'c and the remaining feed water goes to the 2nd column. The pure steam is used as a heating media in the 2nd column and converts part of remaining feed water into steam. In the process the steam itself condenses back into water. This process is repeated till the last coulms each working at low temperature & pressure as compared to the one before it. The steam produced in the last column is condensed in the condensor by feed water as well as cooling water. As external heat is required only to convert the 33% of feed water, the heating energy required is reduced by 67%. |

|

|

Salient Features : |

|

|

|

|

Scope of supply Includes : |

|

|

|