Listing ID #137677

Company Information

Ask for more detail from the seller

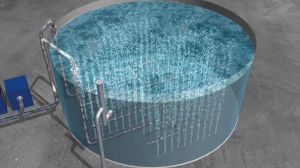

Contact SupplierTrickling filters with rock packing have been a common, simple, and low-energy process used for secondary treatment since the early 1900s. A trickling filter is a non submerged fixed film biological reactor using rock or plastic packing over which wastewater is distributed continuously. Treatment occurs as the liquid flows over the attached biofilm.

The concept of a trickling filter grew from the use of contact filters in the England in the late 1890s. Originally they were watertight basins filled with broken stones and were operated in a cyclic mode. The bed was filled with wastewater from the top, and the wastewater was allowed to contact the packing for a short time. The bed was then drained and allowed to rest before the cycle was repeated. A typical cycle required 12 h (6 h for operation and 6 h of resting). The limitations of the contact filter included a relatively high incidence of clogging the long rest period required, head loss, and the relatively low loading that could be used. Because of the clogging problems, larger packing was used until a rock size of 50 to 100 mm (2 to 4 inch) was reached (critics and tchobanoglous1998).

In the 1950s, plastic began to replace rock in the United States. The use of plastic packing allowed the use of higher loading rates and taller filters (also known as Biotowers) with less land area, improved process efficiency and reduced clogging. In the 1960s, practical designs were developed for rotating biological contactors (RBC), which provided an alternative attached growth process where the packing is rotated in the wastewater treatment tank, versus pumping and applying the wastewater over a static packing. Both trickling filters and RBC have been used as aerobic attached growth processes for BOD removal only, combined BOD removal and nitrification and for tertiary nitrification after secondary treatment by suspended growth or attached growth processes. The principal advantages claimed for these aerobic attached growth processes over the activated-sludge processes are as follows :