Listing ID #3839121

Company Information

Ask for more detail from the seller

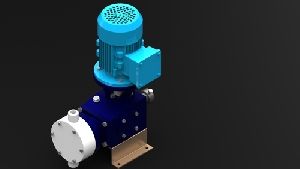

Contact Supplier! Multi-functional and user-friendly: on principle!

The design principles underlying the Meta series involve decades of ProMinent experience and guarantee operator safety at every stage.

Oscillating positive displacement pumps based on the spring cam principle

The drive is a three-phase motor whose drive output is reduced by a worm gear pair, and conveyed via a cam to the connecting rod, producing reciprocal motion. The stroke action is subject to no play and accurate repetition is maintained over a long service life. This is the result of a spring-loaded recuperator which ensures the connecting rod stays in constant contact with the cam (i.e. the spring cam principle). Reciprocal stroke limits may be very finely adjusted which means stroke lengths are extremely precise (1 % graduations for Meta HM).

0.37 kW for 2370 I/h - is enough!

The minimal friction within the drive mechanism ensures high power output from the standard-sized dual-wound three-phase motor (0.1 8/ 0.37 kW, 230/400 V, 50/60 Hz). With its 0.37 kW a triple Meta Pump has enough power to dose 2370 I/h now that's efficient!

A cool head keeps its distance...

The mechanical separation of dosing head and gears effectively prevents seepage of chemicals into the casing and gears.

..and can even dose highviscosity liquids!

The specialised dosing head design, in conjunction with valves particularly suited to accommodate liquid through-flow makes these models ideal for dosing highviscosity liquids. With dosing heads incorporating an integrated heating system, e.g. for glue, syrup or sugar-solutions, or dosing heads in stainless steel (1.4571), or chlorine and acid-resistant Hastelloy C we've got all media options covered, and under control! We can supply manual or timer-controlled rinsing, enabling you to adopt a flexible approach to specialised processes.

Lift off!

The suction lift of ProMinent (regtd) Meta diaphragm dosing pumps creates a water column of 2 to 5 m (dependant upon model). It varies according to the thickness and viscosity of the medium, and the size of the connecting pipework.

A heart of steel: ProMinent (regtd) Meta HM/AM

The heart of the dosing head is the well-proven DEVELOPAN (regtd) dosing membrane: it consists of a steel core, which is vulcanised into a chemical and temperature-resistant EPDM material, strengthened with Nylon webbing, and which is Teflon (PTFE) -coated on the chemical - contact side. This ensures reliable dosing even under varying back-pressures.

Durability comes as standard!

The long service life of these membranes is a result of the symbiosis of material, construction and the maximum movement of 4 and 6 mm. Dosing heads are fitted with precision ball valves. The material variants - Polypropylene, PVC, Teflon and stainless steel 1 .4571 - correspond to current resist ance requirements and allow practically limitless application options for the ProMinent (regtd) Meta.

Reproducibility better than +/- 2%

Dependant upon a stroke length programmed at between 30% to 100% under defined and constant conditions, and provided installation has been carried out correctly reproducibility is better than ± 2%. This ensures the quality of all your technical processes.

The new Meta-generation represents an advance: of 2mm

The increase in the length of the dosing stroke from 4 to 6 mm on the new Meta dia phragm dosing pumps means that in conjunction with newly constructed DN 25 ball valves the ProMinent(r) Sigma series can achieve up to 50% higher dosing capacities - and that's at the same cost and with the same pump size. Using a combination of one main pump and three externally - mounted pumps the operator can count on a maximum dosing quantity of 3.160 I/h (4 x 790 I/h). Work it out for yourself...