Listing ID #4193169

Company Information

Ask for more detail from the seller

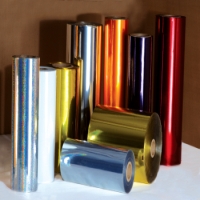

Contact SupplierRoHS approved MPP film is also available with all types of Metallisation

2. Roll Dia

3. Metallization

Slope / Taper / Ramp

Linear slope is maintained while metallization by maintaining the resistance value of 2 Ohm per sq. at heavy edge and gradually achieving 20 ohms per sq. towards free margin side.

4. Advantages of Slope/Taper/Ramp

4. Standard Resistance Values

| Sr. No. | Type of Metallization | Avg. Resistance value | Heavy Edge Resistance value |

| 01 | Aluminum | 2 to 4 ohms/sq | NA |

| 02 | Bi Layer | 6 to 9 ohms/sq | 2 to 3 ohms/sq |

| 03 | Slope/Taper/Ramp | 10 to 13 ohms/sq | 2 to 3 ohms/sq |