Listing ID #6613381

Company Information

Ask for more detail from the seller

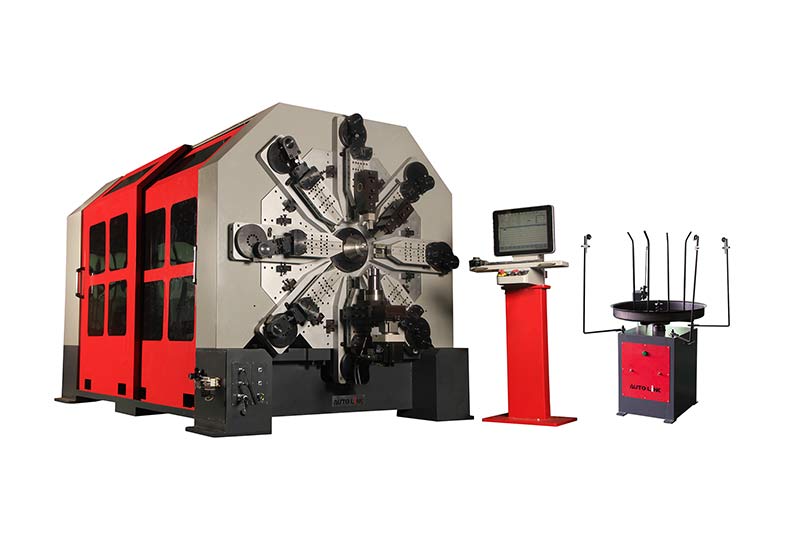

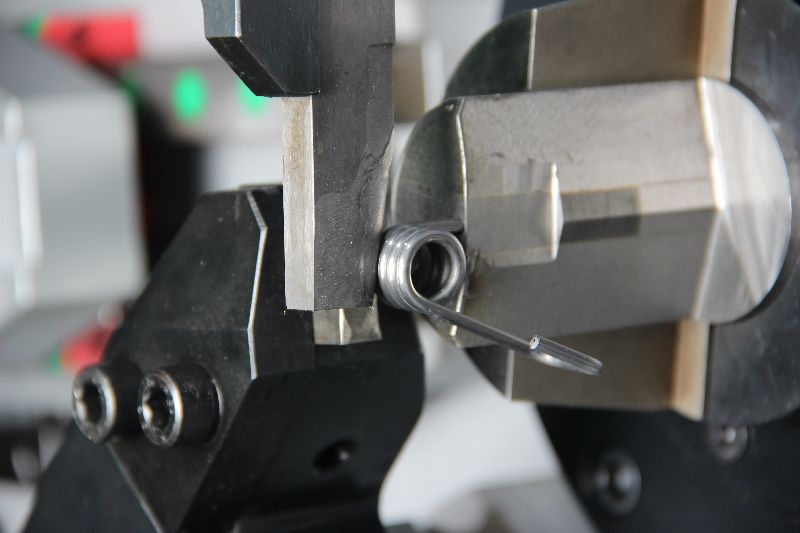

Contact SupplierThe camless 12 axis CNC wire forming machine is widely used for many applications. TheCNC machine comes with a rotary. Hence, they can use a lot of tools simultaneously. It operates at a higher rate of efficiency. The CNC wire forming machine helps to design and produce many simple complexes and output forms. The machine increases the rate of production drastically. The spring forming machines accomplish the complex shapes of wire bend and wire forms.

Auto Link Technology manufactures the complex shapes of compression, extension, tension springs, etc… The machine builds the output as per the customer standards.

Input Materials: Stainless Steel, Aluminium, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc. Then the input wire ranges from 0.5mm to 8.0mm in diameter.

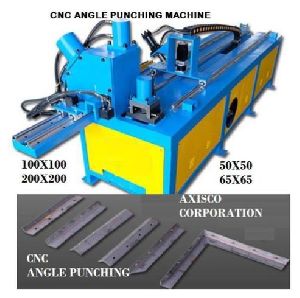

The CNC Wire Forming Machine is of Camless model which comprises of 8 motors with 8 arms. Therefore, the overall efficiency of this machine is higher than the others. It gets the input from the user. The user loads the input wire into the decoiler unit. The capacity of the unit is of 20Kg to 2000Kg. The automatic CNC wire forming machine of 12/14axis helps to discover a wide range of applications. The wire rotary model increases the production speed, and hence it reduces the production time gradually. The bending, holding, punching, softening, or quilling process occurs as per the customer's requirement. Then, the CNC program is set according to meet the industrial need. If the customer requires a simple-shape wire bending or forming, then the lower axes can be preferred.

Features of 12/14 Axis CNC Wire Forming Machines:The 12 axis CNC forming machine work under the principle of Servo motors and CNC programming to make wire forms. Therefore, it requires an efficient working process from the machinery above units. All the machinery processes are controlled with the help of the Controller.