Listing ID #1485490

Company Information

Ask for more detail from the seller

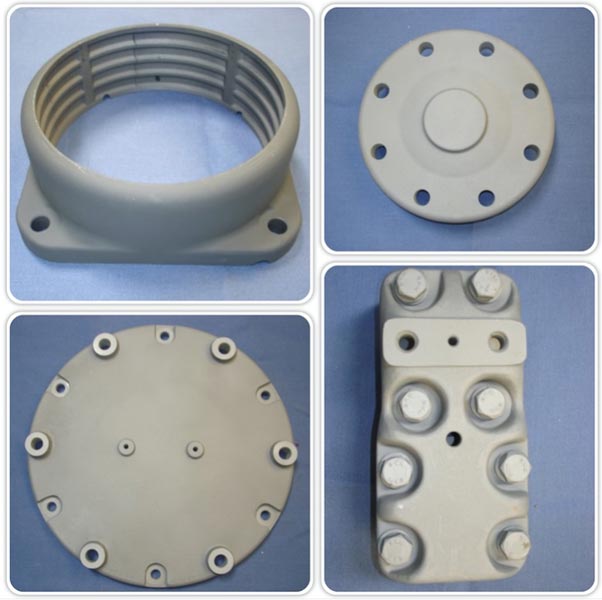

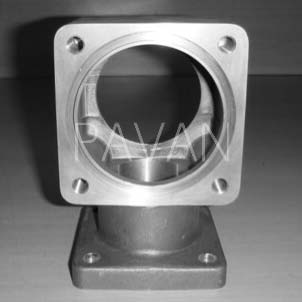

Contact SupplierHere at Pavan Pressure we are specialists in Permanent Mold Castings. Though there are different types of Aluminium Casting methods available to customers today, permanent mold cast is an Ideal Solution when a Casting demands the following :

Better Dimensional Accuracy

Significant Strength

Good Surface Finish

Higher Quantities

Permanent mold typically has a better finish than a sand casting and produces a casting with significantly stronger mechanical properties as well.

This method of casting is achieved by gravity pour into one of the following applications: static or tilt-pour mold machines. Molten aluminum is poured into the mold, either by operator directly or by tilting the mold into a vertical position. In this process, the mold is made in two halves from cast iron or high strength steel. If cores are to be used, they can be metal inserts, which operate mechanically in the mold, or sand cores, which are placed in the molds before closing (semi-permanent molding).

The mold halves are preheated and the internal surfaces are coated with a refractory. If static pouring is to be used, the molds are closed and set into the vertical position for pouring; thus, the parting line is in the vertical position. In tilt pouring, the mold is closed and placed in the horizontal position at which point molten metal is poured into a cup(s) attached to the mold. The mold then is tilted to the vertical position, allowing the molten metal to flow out of the cup(s) into the mold cavity. The various permanent mold techniques static pour and tilt pour offer a variety of advantages for a variety of metal forming applications.

Benefits in using Gravity die-casting:

Gravity and automated tilt gravity machines.

Able to create large scale castings - up to 20Kg casting capacity.

Ideal for small and larger products

Heat treatable alloys giving greater mechanical properties.

Capacity to produce Gravity die castings for medium to high volumes requirements.

Ideally suited for low & high production volume at the lower upfront capital cost.

Ideally suited for converting an existing sand cast product which is increasing in production volume resulting in per unit part price savings.

Sliding core or disposable sand core can be incorporated into the tooling to produce castings with undercuts.