Listing ID #1346676

Company Information

Ask for more detail from the seller

Contact Supplier| The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. | ||||||

| However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. | ||||||

|

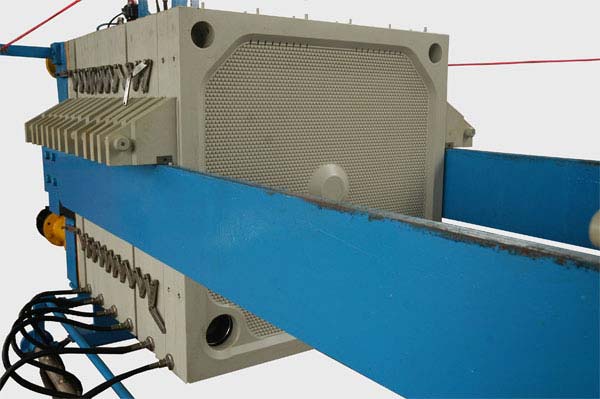

At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber.

|

||||||

|

The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

|

||||||

| Membrane filter plates are used to | ||||||

|

||||||

| This style of filter plate can be installed as | ||||||

|

||||||

|

Because of its simplicity and flexibility, the chamber Filter Press has been widely applied in clarification and dewatering applications. Membrane Filter Press technology is gaining increased acceptance because it reduces subsequent processing or disposal costs for filter cake. In many applications the membrane Filter Press significantly reduces residual moisture content, making this technology attractive for new plants and for upgrading existing facilities. In both cases the careful selection of plate and membrane materials is essential to the successful performance of the process.

|

||||||

|

Membrane Filter Press Plates have a chamber below the drainage surface that can be inflated. The common method used is water pressure, which is generated by pumping into the squeeze cavity to inflate the face of the plate against the filter cake. Membrane Plates are used to reduce the cake moisture content & shorten the filtration cycle time.

|

||||||

|

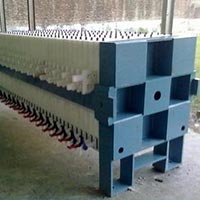

Mix Pack Membrane are the most common configuration (one recessed plate then one membrane plate alternate in the press plate pack). Membrane Plates usually operate at a feed pressure of up to 7 bar and squeeze pressure up to 15 bar. Special plates can be designed for higher feed & squeeze pressure.

|

||||||

|

Replaceable membranes can easily changeable. EPDM thermoplastic and other compounds are used for specific conditions. Plate filling problems are minimized and use of a rubber Membrane enables “empty-chamber” operation without damaging the plate, resulting a considerable reduction in incidents of plate failure. Even if the chamber is not completely filled, the filter cake is squeezed by the inflating filter lever and therefore perfectly dewatered.

|

||||||

|

During the initial phase of the filtration cycle, so-called “fill and filtration” the process is similar to the chamber Filter Press. After reaching a predefined pressure, usually around 3 - 7 bar, depending on the sludge characteristics, sludge feeding is stopped & the rubber membranes inflated, using either water or air as squeeze medium. The cake is hereby compressed and dewatered further. Then the squeeze medium is relieved & the cake discharged.

|