Listing ID #3466216

Company Information

Ask for more detail from the seller

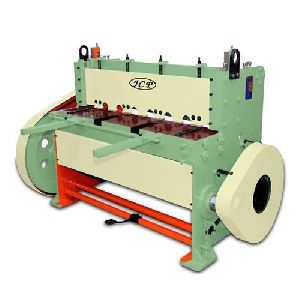

Contact SupplierShubhampress Automation Mechanical Under Crank Shearing Machine have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability.