Listing ID #4851477

Company Information

Ask for more detail from the seller

Contact Supplier

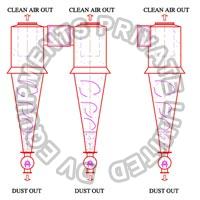

Shanti Multi Cyclone Dust Collectors are designed on Vertex separation science . The dust collectors are designed so to provide cyclonic and rotation effect to separate dense particulate matter in the flue gases . A high circulating air flow is allowed to travel in a hellical partern from the top of the dust collector . This creates higher inertia and follow tight curve this ideal rotation effect will force the dense particulate mater to settle at the bottom of the cone , which in turn is removed manually or mechanically. Multi Cyclone Dust Collectors are more suitable for fuels like Coal , Wood etc.., . It is more effective than Single cone dust collection systems.

All Boiler capacities

Ideally sized ensures efficiency , reliability

Use of Cast Iron Cones & Vanes for very long life for certain abrasive fuels

Negligible maintenance downtime

How Efficient are Cyclone Collectors?

The particle collection efficiency of a cyclone depends on a number of factors, including the dimensions (Length and Diameter) or cyclone, the inlet gas velocity, the particle size and the dust concentration in the gas stream. Collection efficiency tends to increase when inlet gas velocity increases and when particles size and dust concentration increases. Also, smaller cyclones are usually more efficient than are larger cyclones. Large-diameter cyclones are most effective in removing relatively large particles from a gas stream.