Listing ID #3838817

Company Information

Ask for more detail from the seller

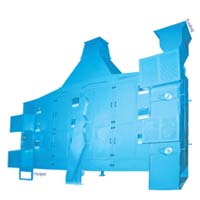

Contact SupplierAvailable for all kinds of wet processing treatments like De-sizing, Scouring and Dyeing. Equipped with an adjustable Tension Control Device, the Maxi-Jig Electronic, operates with absolute controlled tension. Available in 1400-1000-800-300 batch diameter capacities.

For more than 40 years SWASTIK has been engaged in manufacturing. Wet processing Equipments. SWASTIK has been always ahead of others in India in designing and manufacturing. Modern and latest equipment, be it a continuous Dyeing plant or a loop steamer or a Rotary Screen printing Machine or a compressive shrinking Range. Therefore it is not a coincidence that in 1978, SWASTIK was the first in India to launch Combi-Steamer, a concept which has now been adopted internationally. The Present open Width Scouring and Bleaching installation offered by SWASTIK can claim considerable economical and technical advantages. The first continuous Bleaching plant with Combi–Steamer has been in operation for over 12 years now.

| Tension | ||||||||||||||||||

| The pre-set programmed tension remains constant throughout the process. It can be selected for every programme step and remains constant even when reversing, and can be displayed on screen. | ||||||||||||||||||

| Speed | ||||||||||||||||||

| The programmed speed remains constant and is independent of the load . Speed for each step can be programmed as desired and displayed on screen. | ||||||||||||||||||

| Oscillation | ||||||||||||||||||

| When the programme demands a stoppage or at the end of the final run, the machine switches to an oscillating movement. Oscillation can be set between 1 to 5 revolutions, always on the bigger batch side. |

||||||||||||||||||

| Re-Circulation | ||||||||||||||||||

| Bath re-circulation with a stainless steel pump, to obtain uniform dyeing and to improve chemical exchange, can be provided. On request a small chemical addition tank can also be provided. | ||||||||||||||||||

| Dosing | ||||||||||||||||||

|

Dye-stuff and chemical are added as programmed with the help of a dosing system which can be controlled by a PLC. |

||||||||||||||||||

| Salient Features | ||||||||||||||||||

|

| Technical Data | ||||

| Model | MJE 300 | MJE 800 | MJE 1000 | MJE 1400 |

| Roller Diameter | 175 mm. | 275 mm. | 275 mm. | 275 / 325 mm. |

| Roller Face | 1500 -3400 mm. | 1500-3400 mm | 1500-3400 mm | 1500-3400 mm |

| Connected Power | 6 / 9.5 / 14 | 12 / 14 / 17.5 | 14 / 17.5 / 26 | 18 / 27 |

| Tension | 6 - 40 Kg | |||