Listing ID #3720906

Company Information

Ask for more detail from the seller

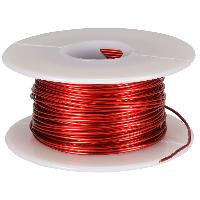

Contact SupplierThe brief description of the process of manufacturing super enamelled copper wire is outlined as below.

The basic raw material is Copper Rod of 8mm thickness which is sourced locally from the copper suppliers like HCL, Birla Copper and Sterlite. Only the best quality of CC Rods made out of imported copper cathodes are used as raw materials. These rods have a copper content of 99.9 % which is in line with the stringent international standards.

From these rods the wire diameter would be brought down to 2 mm by a process known as cold wire drawing through a series of diamond dies The drawn bare wire will then be taken on steel bobbins and will further be reduced through a process of fine drawing in which the required bare size shall be attained. The wire would then be ready to be fed to the enamelling plant.

Before the wire goes to the enamelling section it is passed through an in line pre-annealer, in which the drawn bare wire passes through electrically heated furnace so that the wire becomes softer - the parameters are maintained in such a way that the enamelled wire maintain its brightest luster and with end product free from spring back, which is one of the very essential and important factors to the modern users of enamelled wire.

In enamelling process, which basically consists of the application of the insulation layer on top of the drawn bare copper wire, it is ensured that enamel application is very scientific and every care is taken to give a concentric coat of properly baked coating. During processing on the enamelling machine , the diameter of the conductor, its surface, size of covering etc. are checked at each stage. The different classes of insulation is ensured by the application of the suitable enamel pertaining to that thermal class.

Elaborate tests are carried out both on-line as well after the finished reels are ready samples are sent out to the testing department and checked as per relevant Indian Standards. Records are maintained for each reel and only inspected and checked reels are sent for packing and despatch.

The machines and production processes are designed to give our customers quality assurance at an economic cost.