Listing ID #3515598

Company Information

Ask for more detail from the seller

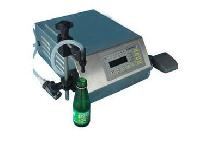

Contact Supplierwe undertake turnkey contract for bulk installation of lpg bottling plants for filling lpg cylinders. These are sophiticated plants with or without carousel. We also provide special instrumentation for complete automation to enable faster and accurate cylinder filling. Bottling plant is a plant where beverages are put into bottles with a cap. These bottles are widely used for storage purposes. Liquefied petroleum gas (lpg) consists mainly of propane, propylene, butane, and butylene in various mixtures. However, in the united states, the mixture is mainly propane. It is produced as a by-product of natural gas processing and petroleum refining. The components of lpg are gases at normal temperatures and pressures. Lpg bottling plant is a plant where lpg is put into bottles for storage. The plant has the facility to recieve bulk lpg by pipeline from a reliable source or any area. This is the safest and the cheapest way of transporting bulk lpg. The plant is equipped with hydraulic cylinder testing equipment for periodic testing of the cylinders. To ensure safe and accurate filling of the cylinders well experienced technical people should only be employed in the working of the plant.