Listing ID #6512931

Company Information

Ask for more detail from the seller

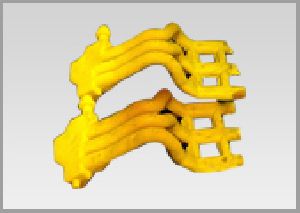

Contact SupplierA pattern is made from polystyrene foam, which can be done by many different ways. For small volume runs the pattern can be hand cut or machined from a solid block of foam; if the geometry is simple enough it can even be cut using a hot-wire foam cutter. If the volume is large, then the pattern can be mass-produced by a process similar to injection molding. Pre-expanded beads of polystyrene are injected into a preheated aluminum mold at low pressure. steam is then applied to the polystyrene which causes it to expand more to fill the die. The final pattern is approximately 97. 5% air and 2. 5% polystyrene. Pre-made pouring basins, runners, and risers can be hot glued to the pattern to finish it. [1]

next, the foam cluster is coated with ceramic investment, also known as the refractory coating, via dipping, brushing, spraying or flow coating. After the coating dries, the cluster is placed into a flask and backed up with un-bonded sand which is compacted using a vibration table. The refractory coating captures all of the detail in the foam model and creates a barrier between the smooth foam surface and the coarse sand surface. Secondly it controls permeability, which allows the gas created by the vaporized foam pattern to escape through the coating and into the sand. Controlling permeability is a crucial step to avoid sand erosion. Finally, it forms a barrier so that molten metal does not penetrate or cause sand erosion during pouring. Once the sand is compacted, the mold is ready to be poured. Automatic pouring is commonly used in lfc, as the pouring process is significantly more critical than in conventional foundry practice.

there is no bake-out phase, as for lost-wax. The melt is poured directly into the foam-filled mold, burning out the foam as it pours. As the foam is of low density, the waste gas produced by this is relatively small and can escape through mold permeability, as for the usual outgassing control.

advantages and disadvantages

this casting process is advantageous for very complex castings that would regularly require cores. It is also dimensionally accurate, maintains an excellent surface finish, requires no draft, and has no parting lines so no flash is formed. The un-bonded sand of lost foam casting can be much simpler to maintain than green sand and resin bonded sand systems. Lost foam is generally more economical than investment casting because it involves fewer steps. Risers are not usually required due to the nature of the process; because the molten metal vaporizes the foam the first metal into the mold cools more quickly than the rest, which results in natural directional solidification. foam is easy to manipulate, carve and glue, due to its unique properties. The flexibility of lfc often allows for consolidating the parts into one integral component; other forming processes would require the production of one or more parts to be assembled.

the two main disadvantages are that pattern costs can be high for low volume applications and the patterns are easily damaged or distorted due to their low strength. if a die is used to create the patterns there is a large initial cost.

We Castomech Technology LLP, based in Gandhinagar, Gujarat, India, are one of the well-known Manufacturers and Suppliers of a large range of Sand Processing Machineries. All of our items are manufactured in a high-tech production facility by a team of skilled technicians, engineers, and quality controllers.

We diligently adhere to international quality standards in our manufacturing and packaging procedures to ensure that our customers needs are met. Our team members are experts in various industries. We were able to complete the bulk production orders of our customers within the time range set thanks to their genuine and focused efforts.

Production Facility:

We are dedicated to presenting our products in the best possible packaging. To do this, we have built a well-organised packaging and warehousing department. To ensure scratch-free transportation, we employ high-quality basic components such as plastic, paper board, and wooden boxes.

Our Team:

Our working team is made up of highly qualified, professional, and experienced individuals. These individuals are experts in their fields. We recruit people based only on their job abilities, qualifications, and experience. Furthermore, we hold training courses regularly to provide our personnel with the most up-to-date skills and work approaches.

Our dedicated team collaborates closely with one another to achieve an organisation's goals. Aside from these, our team members are constantly developing fresh concepts for delivering high-quality products.