Company Information

Ask for more detail from the seller

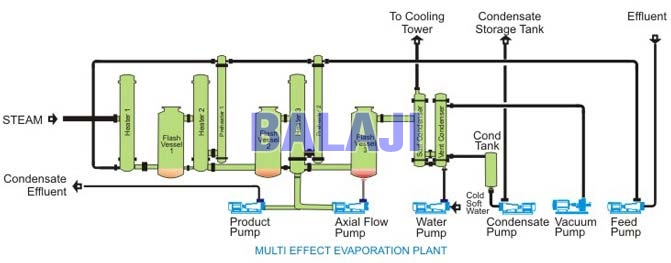

Contact SupplierBraj Projects Pvt.Ltd., every plant is tailor – designed to suit various process conditions like; Feed Temp, Feed Concentration, Product Concentration and Characteristics of Material like Heat Sensitivity, Flow Characteristics, Corrosion & Scaling tendencies.

Details :

Post Evaporation Drying :

Based on the available infrastructure and the pollution norms various Post evaporation methods are employed by industries are as follows :