Listing ID #3832691

Company Information

Ask for more detail from the seller

Contact Supplier|

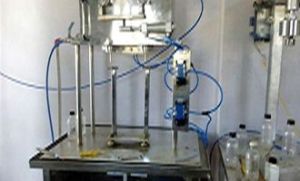

We feel proud to introduce ourselves as one of the prominent manufacturers and suppliers of Liquid Filling Machine (Semi-Automatic) from Ahmedabad, India. We bring for our client’s semi automatic liquid filling machines, which are fabricated as per the international norms and also as per the specifications given by the clients. These machines are used for fill all kinds of liquid stuffs like: ghee, water, edible oil, hair oil, juices, sauce, lubricating oil, shampoo and pharmaceutical drugs in bottle, jar our pouch. It is simple in design that assures easy operations, which increases output of these machines. These Liquid filling machine also known as liquid filler and liquid dispenser or liquid dispensing machine which is suitable to fill 1ml to 5000ml of any liquid in bottles, cans, jars, tubs.

Semi-Automatic Liquid Filling Machines, offered by us is available with PLC control as well as optical kit support for handling volumes less than 100 ml. These machines are also available with single way nozzle for zero drip operations, these meet GMP standards and come with jacketed hopper with temperature control and heating arrangement support. These Liquid Filling Machines (Semi-Automatic) consist of filling Nozzles, S.S. container platform, Container Centering device, Syringe Holders, HDPE Tubes and pipes and on line starter. These filling machines have compact design, versatile and enclosed in stainless steel elegantly matt finish body.

|