Company Information

Ask for more detail from the seller

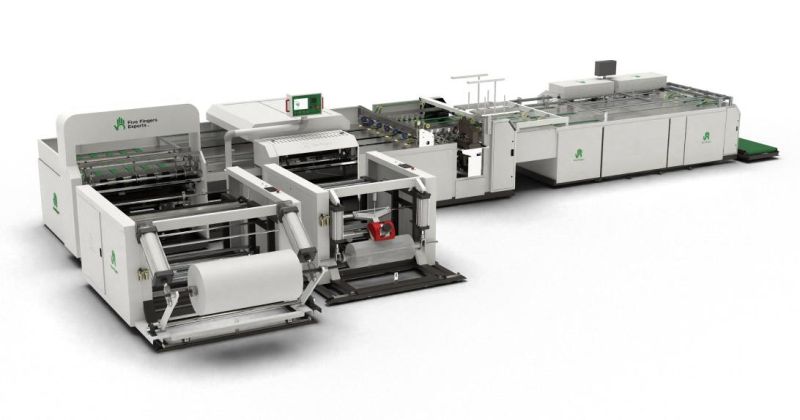

Contact SupplierOur FFN-Liner with Hemming Machine is a fully automatic, modern machine designed to produce high-quality PP woven bags with liner insertion and hemming functionalities. This advanced equipment ensures efficient, reliable, and precise production of bottom-stitched liner-inserted bags, catering to diverse industrial needs.

Key Features

Automatic Loading System:

Facilitates easy loading of fabric using either pneumatic or chain models, customizable based on client requirements.

Edge Position Controller (EPC):

Ensures consistent fabric alignment, even in case of variations in fabric edges, enhancing the precision of the production process.

Roll Feeding and Cutting System:

Hot Cutting: Suitable for non-laminated fabric.

Cold Cutting: Suitable for laminated fabric.

Size Adjustments: Controlled by an HMI with a PLC system, allowing customization of cutting sizes through a touchscreen interface.

Pulling Conveyor: Efficiently pulls the cut fabric, ensuring seamless operation.

Servo-Controlled Liner Insertion System:

Inserts cut liners into PP woven bags automatically, ensuring consistently well-lined bags.

Stops the entire operation if no fabric is received from the cutting unit due to roll completion or other issues.

Delivery and Stacking Unit:

Automatically delivers, counts, and stacks output bags according to pre-set quantities.

Mouth Opening and Hemming:

Specialized for aligning and hemming the mouths of PE liner bags and PP woven sacks.

Ensures precise folding and sealing of the bag mouth and inside liner.

Technical Specifications

Fabric Width for Liner Inserting: 350 - 700 mm

Fabric Width for Hemming: 450 - 650 mm

Maximum Diameter of Fabric Roll: 1200 mm

PE Film Width: +20 mm (bigger than the fabric)

PE Film Thickness: 0.01 mm

Cutting Length of Fabrics: 600 - 1200 mm

Cutting Accuracy: +/- 1.5 mm

Stitch Range: 7 - 12 mm

Production Speed:

Liner Inserting: 20 - 38 pcs/min

Hemming: 10 - 18 pcs/min

Liner Length: 3 - 10 cm longer than the outer bag

Power Supply: 3 Phase

Advantages

Efficiency: High-speed production ensures maximum output with minimal downtime.

Ease of Maintenance: Designed for easy maintenance, reducing operational costs and downtime.

Customization: Adaptable to various sizes and requirements, providing versatility in production.

Professional Consulting: Expert support for setup and operation, ensuring optimal performance.

Enhance your production line with the FFN-Liner with Hemming Machine, ensuring high-quality, reliable, and efficient production of PP woven bags with liner insertion and hemming.