Listing ID #1369817

Company Information

Ask for more detail from the seller

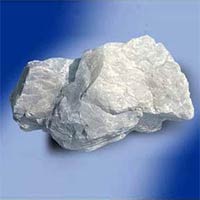

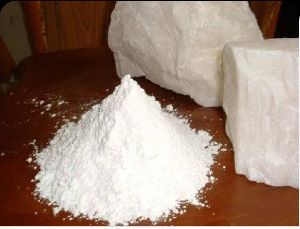

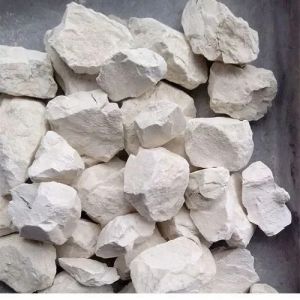

Contact SupplierWe are counted amongst the top Suppliers and Exporters of Limestone Lumps from Chhattisgarh, India. We are associated with trustworthy vendors, who process the Limestone Lumps using the latest technology in compliance to set industrial standards. We properly package the lumps in high-grade materials before dispatching it to the customers. Customers can get in touch with us for ordering Limestone Lumps in bulk at reasonable rates.