Listing ID #937177

Company Information

Ask for more detail from the seller

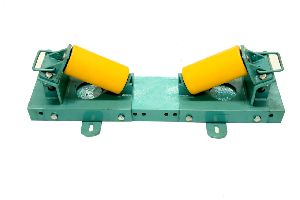

Contact Supplierwe are offering leveler rollers.

application

leveler rollers are used in the ctl lines. these rollers are being utilized in heavy as well as light levelers (cut-to-length line). the thickness of the coil handled varies from 0.2 mm to 10 mm and the width varies from 0.5 m to 3 m. the linear speed of the coil is up to 80 mpm.

nomencleature

work (pinch) roller, intermediate roller, back-up roller

details

the leveler rollers are very critical and the barrel diameter of the rollers has to be controlled within very fine tolerances for effective functioning of the equipment. besides this, these rollers are subject to two types of tilting forces.

materials

the elasticity of the material is the key property to be considered for material selection. the suitable grades of alloy steel which can simultaneously meet the required combination of elasticity, toughness and surface hardness are used to manufacture these rollers.

quality control

the bars are nd tested (in proof machined condition) to determine surface internal defects. the rollers are then subjected to the appropriate heat treatment cycles. the degree of surface hardness obtained after heat treatment is measured. the rollers are then ground to attain the fine tolerances (which ensures proper functioning).