Listing ID #3848913

Company Information

Ask for more detail from the seller

Contact SupplierDue to pre heating of parathas it won’t stick each other while packing. During preheating only one percentile water is evaporating . ie. Only skin is Preheated.

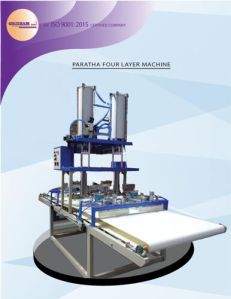

Aarbee food manufacturing machines include paratha (parantha) and parotta making machines.

Our clients make authentic Malabar parottas through our parotta/paratha making machine. Our specialised food machines also ensure that multiple variants and similarly prepared foods could be easily made with minimal adjustments.

For example, our paratha making machines are used globally to produce layer paratha (lachha paratha) and alu parathas.

“Our parotta/paratha (parantha) making machines serve clients in Coimbatore, across the state, across India, and also to a global clientele spanning 4 continents.”