Listing ID #6702049

Company Information

Ask for more detail from the seller

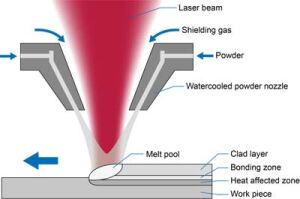

Contact SupplierCladding is a welding procedure that puts weld metal on the surface of the work, as opposed to joining two pieces of material. Generally, this is used for corrosion resistance or wear resistance and frequently a different material is used for the clad than for the base metal. In hot wire welding, the power supply controls the heat of the filler wire prior to its introduction into the weld puddle. Arc energy that would usually go into melting the wire provides more penetration, while heating of the wire almost to the melting point by a separate power supply increases deposition beyond that possible with standard cold wire TIG. In cladding applications where the part is rotated, the hot wire solution can result in weld deposition that approaches MIG speed, but with TIG quality. Laser cladding is realized either as wire (laser hot wire cladding) or powder cladding. The laser beam creates a molten pool at the workpiece surface, to which is simultaneously added the laser coating material (wire or powder) molten by the laser. The exposure time is short, which creates only a short delay as the cooling is quick. The result is a layer that is connected with the basic material metallurgically. It is tougher than those coatings created by thermal spraying, and compared to hard chromium plating, for example, it is harmless to health, too.

Advantages: