Listing ID #4678586

Company Information

Ask for more detail from the seller

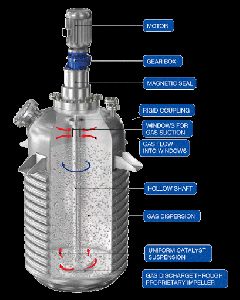

Contact SupplierReactor is vessel or system in which chemical Reaction prodeeds and Reactants converts in Production.Design of Chemical Reactor Varies Widely with process Parameters..Due to transparency and Universal Corrosion resistance;Borosilicate Glass Is preferred Material of Construction for Kilo lab and Pilot plants and Production for small batches also

UD Technologies supplies Glass Batch Reactor in Spherical and Cylindrical Shapes with 10 liter to 500 liter volume.

Cylindrical Shape is widely used considering Geometric and Kinematic Similarity with Commercial Reactors

The designs of Batch reactor Jacketed Glass Vessel or Filter Reactor can be further modified as per client’s requirements such as :

Glass Reactor For Scale Down Studies

UD Technologies holds expertise in offering a wide range of products that includes industrial glass equipment, acid recovery plants, bromine recovery plant, glass pilot plants and etc. We are an eminent Manufacturers and Suppliers of these products in India. The entire range that we offer is manufactured using supreme grade components and progressive technology ensuring the finest quality. Robust construction, excellent performance, corrosion resistant, easy operation and longer functional life are some of the main specifications of our products. Moreover, we can make available products in customized packaging options according to the varied demands of buyers. One can avail these products from us at the market-leading prices.

Based in Vadodara (Gujarat), UD Technologies was positioned in the year 2014. Under the headship of our skilled mentors, we have been able to establish a strong foothold in the industry.

Quality Approved

The range that we offer is methodically inspected in various quality parameters in order to leave no scope of defects. Besides this, our products are packaged in robust packaging material so as to avoid any kind of damages while delivering.

Our Team

With the help of our dedicated professionals, we are able to meet the expectations of our valuable customers in the most successful manner. In addition to this, our team is technically updated and has immense knowledge of this field.

Nationwide Reach

We are associated with reliable logistic agents that help us to reach all across the nation with great ease. Moreover, our modern transit facilities enable quick and safe delivery of products ensuring complete client satisfaction.