Company Information

Ask for more detail from the seller

Contact SupplierJOGANI Brass Coated Microsteel FiberDescription:

JOGANI Brass Coated Microsteel Fiber is a type of reinforcing fiber used in concrete and other construction materials. It combines steel fiber’s strength with a brass coating, enhancing both durability and performance.

Key Features:

Brass Coating: The brass coating on the microsteel fibers helps to improve bond strength between the fiber and the concrete matrix, leading to better crack resistance and durability.

Microsteel Fiber: The fibers are extremely fine, which improves the distribution within the concrete mix and enhances its structural properties.

Reinforcement: These fibers provide reinforcement to concrete, helping to improve tensile strength, impact resistance, and crack control.

Durability: The brass coating provides corrosion resistance, which is particularly useful in environments where the concrete might be exposed to moisture or aggressive chemicals.

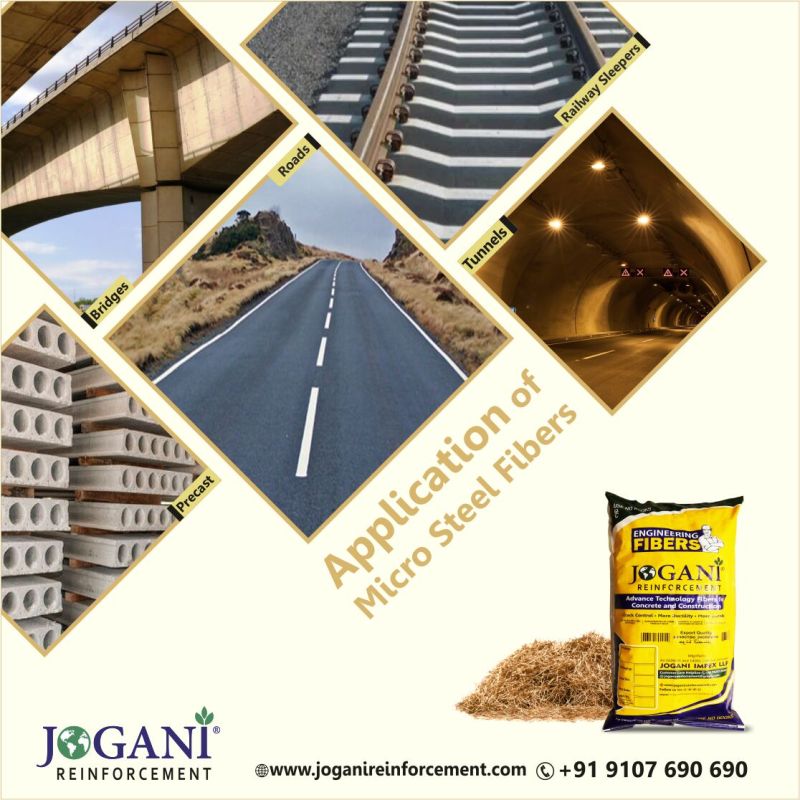

Applications:

Concrete Construction: Used in concrete to improve its structural integrity, particularly in applications where high strength and durability are required.

Industrial Flooring: Enhances the performance of industrial flooring by improving impact resistance and reducing wear.

Precast Concrete Products: Used in the production of precast elements like beams, columns, and panels for added strength and durability.

Reinforced Concrete: Ideal for applications requiring additional reinforcement in bridges, roads, and buildings.

Benefits:

Enhanced Strength: Improves the tensile and flexural strength of concrete.

Crack Reduction: Helps reduce the formation of cracks due to thermal expansion or shrinkage.

Improved Bonding: Brass coating provides a strong bond with the concrete, ensuring that the fibers remain effective over time.

Corrosion Resistance: Brass coating offers resistance to corrosion, extending the lifespan of the concrete.

Usage Instructions:

Mixing: Add the fibers to the concrete mix during the batching process. Ensure they are evenly distributed throughout the mix.

Dosage: The amount of fiber to be used will depend on the specific requirements of the project. Typically, dosages range from 0.5% to 1.0% by volume of concrete.

Application: Follow standard procedures for pouring and finishing concrete. The fibers should not affect the handling or finishing of the concrete mix.

Safety and Handling:

Protective Gear: Wear appropriate protective gear such as gloves and masks when handling the fibers.

Storage: Store in a dry place to prevent any moisture from affecting the fibers.