Company Information

Ask for more detail from the seller

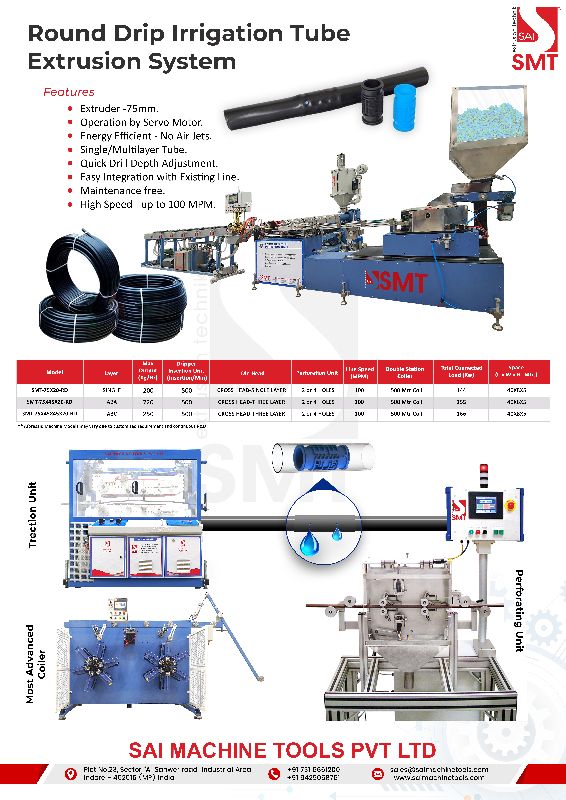

Contact SupplierROUND DRIP TUBE EXTRUSION SYSTEM has everything that a successful drip irrigation pipe requires for. It is accessible with different quality components that allow for high speed perforating and inserting. Round Dripper Irrigation Tube Extrusion Line manufactured and supplied by Sai Machine Tools PVT. LTD has operational efficiency as well as extended serviceability. Overall construction of the production machine is robust and durable. It can effortlessly deal with corrosion, impact, shocks and other disruptions.

Features :

Features :