Listing ID #4167984

Company Information

Ask for more detail from the seller

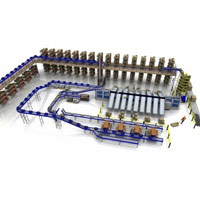

Contact SupplierControlling costs, improving quality and competing in dynamic environments are few of the several challenges that manufacturing industries encounter. Global Autocon plays a key role in countering these challenges by introducing integrated assembly lines with a systematic approach thereby eliminating unwanted processes, introducing relevant quality checks at appropriate inspection points and improving overall efficiency.

Regardless of the project size, Global Autocon works with our clients to develop highly customized solutions to integrate the manufacturing processes so that our clients rest assured of perfect quality, standardization, flexibility, minimal waste, transparent process and cost reduction

Global Autocon assembly lines mark a transition into a new way of business for our clients through the implementation of efficient design-to-assembly processes. Our integrated assembly lines thereby represent a significant shift in the way businesses operate and help our clients to remarkable increase in throughput.

In the current situation of competitive business around the world, most of the manufacturing industries are under huge pressure to reduce cost and cycle time of a product. While manufacturing a group of related products, there are various planning decisions that has to be made, like:

With the help of the integrated assembly lines, with a systematic approach eliminates the unwanted process through improvements in the assembly line process. Most of the defects occur during the assembly process and therefore the quality of the assembled items should be inspected at inspection points along the assembly line. In this case the tasks are assigned to respective assembly stations and the number and location of the inspection points is identified to minimize the cycle time of the line.

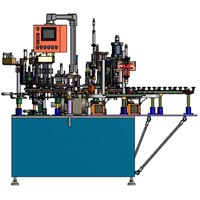

The integrated assembly lines are flexibly engineered to specific manufacturing needs, this helps in frequent change production processes. These changes happen due to changing customer demands and/or market requirements. An integrated production line is comprised of a series of workstations which is linked by a transfer system and an electrical control system. Each workstation performs a specific operation and the product is processed and moves ahead step by step along the line in a pre-defined production sequence.

Such type of production line does not include direct involvement of people while performing the operation. Most/part of the process of the production is completed by mechanical equipment and systems. So in such type of environment, the tasks of human are more likely to

All the Industries where Integrated Assembly line is implemented have a peace of mind for: