Listing ID #713276

Company Information

Ask for more detail from the seller

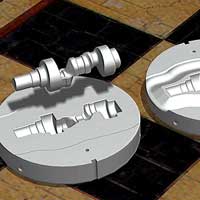

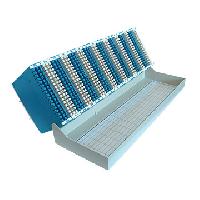

Contact SupplierThe company is a prominent Manufacturer, Exporter & Supplier of Injection Moulding Dies. The Injection Moulding Dies, offered by the company, are known for their flawless operations and long life. The company is offering a quality range of the Injection Moulding Dies at the market leading prices across the global markets. Working