Listing ID #3695326

Company Information

Ask for more detail from the seller

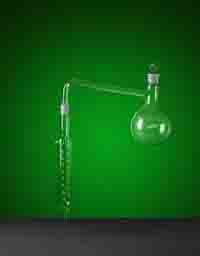

Contact SupplierWhen spherical vessels are used as Stirring vessels or reboilers, the top branch in generally used for the column or stirrer. The side branches on standard vessels are generally DN 25, DN 40 or DN 100; DN 25 and DN 40 being at 10° to the vertical (45° on type VSU) and DN 100 being at 45°. The only exception to this are type VSD spherical vessels which have DN 50, DN 80 and DN 150 side branches at 90° to the vertical and are used mainly in boiler circulatory systems. The smaller branches are normally used for such components as thermometer pockets, resistance thermometer and feed pipes. The DN 100 branches are normally used for charging solids or for the connection of vapour pipes when the top branch is used for a stirrer.