Listing ID #3903079

Company Information

Ask for more detail from the seller

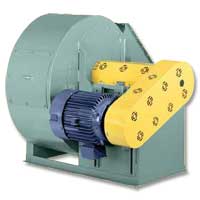

Contact SupplierIn a Steam Boiler operation assembly, Industrial Fans and Blowers are the heart of the system. They are responsible for all other subsequent operations taking place in a boiler i.e, combustion of fuels, generation of hot gases and transportation of flue gases through boiler tubes and other equipment.

Thermodyne Engineering System has more than 20 years of experience in manufacturing Industrial blower fans according to the system requirement. We believe that every system has a room for efficiency improvement and it can be increased to a greater extent with proper designing and operation of fans and blowers.

Depending upon the design of blades and its geometry there are 2 types of fans that serve the basic function of forcing the air into the system or drawing the air out from the system.

Every fan is unique and is manufactured keeping in mind the capacity of gas it needs to handle and system head requirement.

Forced Draft fans are used to force air into the combustion chamber, where it mixes with the fuel being supplied. FD fan is used to regulate an appropriate amount of air to fuel ratio in the combustion chamber to maximize the fuel efficiency. Amount of air required for the complete combustion of fuel is calculated using stoichiometry involved during the reaction of the fuel with air.

Generally, 30% excess air is provided for complete combustion of fuel but the excess air quantity depends upon the system to system and must be controlled during the operation.

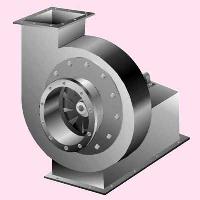

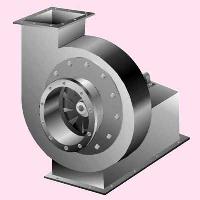

Induced Draft fans are used in a system to draw flue gases from the combustion chamber and through the rest of the boiler assembly (Air Pre-heater, Dust Collectors, ESPs etc.) to the stack. Flow depends upon the amount of flue gases need to be drawn and head required to draw flue gases from the system depends upon the sum of pressure drops of all equipment installed in the path of the fan.

We, at Thermodyne, design, manufacture & supply both Induced and Forced Draft fans for your system. We have also developed an online calculator for the customers for calculating the motor power required for operating fan at maximum capacity and head.

Specially designed, high-efficiency fans are offered for all boiler applications:

All the fans and its impellers are analyzed for balancing and vibrations before fitments to give increased efficiency, reduced power requirement, trouble-free and reliable performance.

Contact our Sales team for Industrial Blower Fans.