Listing ID #7426426

Company Information

Ask for more detail from the seller

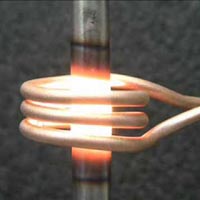

Contact SupplierThe VEL HardTech series represents cutting-edge induction hardening, annealing, and tempering systems tailored to meet the evolving needs of the heat treatment industry.

We offer complete turnkey solutions that include an advanced Induction Power Source, CNC/PLC control automation, high-frequency transformer, and custom-designed coils tailored for specific jobs. Our solutions also feature job-specific scanning (horizontal or vertical), single-shot fixtures, and rotary or indexing tables. They seamlessly integrate with semi or fully automated job loading and unloading facilities, ensuring that the system fulfils your hardening requirements effectively.

Features:

Technical specification:

The Induction Hardening System (VEL/IH Series) is specially designed for Induction Hardening of components on turnkey basis complete with > Induction Power Source > CNC/PLC based servo motor driven Vertical/Horizontal Scanner > Water circulating & Cooling system and Quenching system > Semi-Automated/ Fully Automated job loading/unloading facility (optional)

| TYPE | VEL/IH50 | VEL/IH100 | VEL/IH200 | VEL/IH400 |

| Inverter | IGBT based Inverter | |||

| Converter | Thyristor based Full bridge Rectifier | |||

| Incoming Voltage | 415 V, 3phase, 50 Hz, 4 wire | |||

| Input Feeder Rating | 100 amps | 200 amps | 400 amps | 800 amps |

| Output Power | 50 kW | 100 kW | 200 kW | 400 kW |

| Output Frequency | 1-100 kHz (as per job requirement) | |||

| Output Voltage | 0 – 400 V | 0 – 400 V | 0 – 400 V | 0 – 400 V |

| Max. Output Current | 1000A max | 2000A max | 4000A max | 8000A max |

| Accessories | Description & Features |

| Job Handling Fixture |

|

| Cooling System |

|

At Vel Innovative, our organisation is locked in the manufacturing and trading of high-performing induction machines. We use our extensive experience to create flexible Solid State Inverter Induction machines for Heating, Annealing, Brazing, Hardening and various other purposes.

Our Business

With our ability, we have provided more than 500 High-Frequency Induction Heating machines, Induction Brazing machines, Induction annealing machines and so on to the national and worldwide market. Utilisation of high-innovation parts within the machines guarantees highspeed. Giving driving force to the client's business, our Induction machines offer maximum productivity in the least time.

Established in 1971 in Mumbai, Vel Innovative began its journey to victory by advancing handle control types of equipment. After this tremendous victory, the company startedmanufacturing different electronic supplies. Ms. Bharthi is the organisation's CEO, beneath whose headship we have set a solid toehold within the worldwide market.

Our Standing inthe Industry

Nowadays, we have carved a speciality as one of India's major Induction Brazing Machine Producers and providers. We have outlined our business approaches to offer the most significant benefit to the clients with the most minor speculation.

We enable clients by advertising the predominant induction machines at exceptionally reasonable costs. Because of our suitablebusiness approaches, we have earned honours from gigantic clientele based in India and overseas.