Listing ID #7426532

Company Information

Ask for more detail from the seller

Contact SupplierInduction forging process is energy efficient, rapid / instant heating process as it provides superior productivity, consistent quality, flexibility and reliability.

VEL ForgeTech series is specially designed and manufactured for heating metal in forging, rolling, stamping extrusion, upsetting and other forming applications to obtain desired shape in Presses, Bending Machines, Forming machines, etc on turnkey basis. They are designed to heat any dimension of billets, bars, blocks, slabs etc in full or partially in materials as diverse as Steel, Stainless Steel, Brass, Bronze, Aluminium, Copper, Titanium, Silver, etc and their alloys

INDUCTION HEATING POWER SOURCE

Induction Heater , Thyristor / IGBT based, of varying power capacities ranging from 400 kW to 1600 kW consisting of Inverter modules auto tuned to Resonant Frequency ranging from 1 to 20kHz, incorporating Microcontroller (µC) based electronic controls, Protection/Trip circuits, Interlocks etc, Output Matching Transformer, Inductor Assemblies etc.

CONTROL AND FEEDBACK SYSTEM

PLC based control system & SCADA for automated system & process. All alarms generated and machine / process parameters displayed / controlled from HMI on Control Panel / SCADA.

Non-contact pyrometers are used to measure the part temperature to achieve precision temperature control, to maintain temperature consistency, feedback for hold modes, option to reject job for over/under job temperatures etc.

HEATING STATION

The induction coil is completely contained within the steel shell and is isolated from the job with a refractory coating. There is no chance of hot slag or other materials from the furnace contaminating the room.

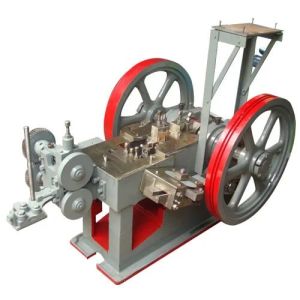

LOADING/ UNLOADING & FEEDING SYSTEM

Semi-Automated/ Fully Automated job loading/unloading facility are available, such as Vibratory, magazine, step, or bowl feeders, V-flight and other conveyor feeders to move billets into drive position, Pneumatic or hydraulic horizontal pusher, tractor drive, pinch roller drive or walking beam arrangement for moving job through the inductor, High-speed conveyors to rapidly deliver the hot job to press operator or robot pick up point, etc

| TYPE | VEL/IHS400 | VEL/IHS800 | VEL/IHS1200 | VEL/IHS1600 |

| Output Power | 400kW | 800Kw | 1200Kw | 1600kW |

| Input Feeder Rating | 800Amps | 1600Amps | 2400Amps | 3200Amps |

| Incoming Voltage | 415 V, 3phase, 50 Hz, 4 wire | |||

| Output Frequency | 1-20 kHz (as per job requirement) | |||

At Vel Innovative, our organisation is locked in the manufacturing and trading of high-performing induction machines. We use our extensive experience to create flexible Solid State Inverter Induction machines for Heating, Annealing, Brazing, Hardening and various other purposes.

Our Business

With our ability, we have provided more than 500 High-Frequency Induction Heating machines, Induction Brazing machines, Induction annealing machines and so on to the national and worldwide market. Utilisation of high-innovation parts within the machines guarantees highspeed. Giving driving force to the client's business, our Induction machines offer maximum productivity in the least time.

Established in 1971 in Mumbai, Vel Innovative began its journey to victory by advancing handle control types of equipment. After this tremendous victory, the company startedmanufacturing different electronic supplies. Ms. Bharthi is the organisation's CEO, beneath whose headship we have set a solid toehold within the worldwide market.

Our Standing inthe Industry

Nowadays, we have carved a speciality as one of India's major Induction Brazing Machine Producers and providers. We have outlined our business approaches to offer the most significant benefit to the clients with the most minor speculation.

We enable clients by advertising the predominant induction machines at exceptionally reasonable costs. Because of our suitablebusiness approaches, we have earned honours from gigantic clientele based in India and overseas.