Listing ID #4180258

Company Information

Ask for more detail from the seller

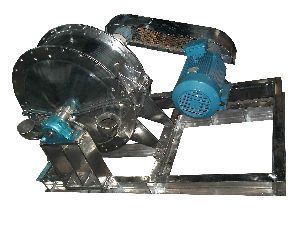

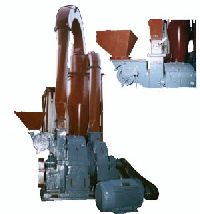

Contact SupplierImpex Mill is a screenless pulverizer suitable for grinding hard and brittle materials

like turmeric, minerals, etc. to a fineness of 100 to 300 Mesh BSS. It is done by

continuous impact of rotating hammers against grinding liners. The raw material is

fed into the rotary feeder from inlet hopper and spills into the grinding chamber.

Strong hammering action breaks lumps into small particles. At the same time the

blower sucks the air towards the whizzer classifier. Whizzer classifier doesn’t allow

oversize particles to pass and returns it into the grinding chamber, where after

regrinding the desired fineness is achieved.

|

MODEL |

FIM – 15 |

FIM – 22 |

FIM – 25 |

FIM – 32 |

||

|

POWER H.P. |

10 |

20 |

30 |

60 |

||

|

CAPACITY (Kgs/Hr.) |

50 |

100 |

200 |

400 |

||

|

Fineness Achievable |

Upto 100-250 Mesh BSS |

|||||