Listing ID #1318528

Company Information

Ask for more detail from the seller

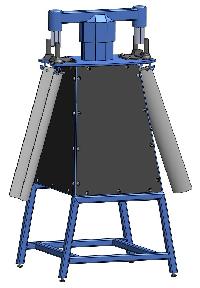

Contact SupplierThe H.S.I design is genius of simplicity. This design is actually the most effieient type of secondry teritiry and quartenry crushing applications. This H.S.I are performing the magic of increased production, more uniform product gradations and cubical shape products.

The material to be reduced is fed in to hopper from which, it falls directly in to the center of H.S.I impeller rotating at high speed. The material is then uniformly flug outwards by centrifugal force. The rotating speede of the impeller assembly along with the precision speed and angles outwards and forwards against the stationary. Other flying particles each impact reduces the material further. The plates are positioned at sufficient distance from the rotating impeller to allow free body impacting. The resulting fragmented cubical product is discharged by gravity. Output gradation within limits can be controlled by varying these two fctors Impeller Speed

The Feed material characteristics. The H.S.I gives superior cubical shape product with excellent gradation at reduced horse power with low maintenance cost.

Application

Aggregate Industries :

| Size | H.P | Max Feed Size | RPM | Capacity In Tan/Hour | Approx Wt. Kg |

|---|---|---|---|---|---|

| H-8 | 40 | 65 mm | 750/850 | 30 | 5200 |

| H-10 | 60 | 90 mm | 450/550 | 55 | 8500 |