Company Information

Ask for more detail from the seller

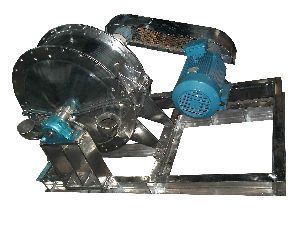

Contact SupplierWe are offering impact pulverizer.

Pulverizing mills are recommended for medium fine grinding of soft semihard materials. Appropriately sized mill chamber prevents build-up of deposits and blocking of the machine by fatty & sticky products. Cool powdering operation retain vital properties like colour, taste, flavour etc. To its optimum levels. Changeable grinding elements offer versatility to cater applications like pulverizing, de-fibreizing, wet grinding, mixing, de-agglomeration, dispersion, hot air drying etc. This is of paramount importance to the user. Centrally fed material gets powdered step by step between rotor and stator, moving radically outward for a bottom discharge through sieve. Clearance, configuration & grinding element design determines results.

Features of our impact pulverizer:

hammer and liners are available in different shapes and construction like ms, hi mn steel hardened alloy steel, stainless steel etc., to suit the material

most suitable and convenient range to pulverize the material up to 60 - 80 mesh

robustly constructed machine for crushing different spice, chemicals, ayurvedic herbs, agro products

used without cyclone and dust collector for bigger output particle size and for fine material, a cyclone with dust collector is used

different type of material for liners and hammer as per client product for better result and best life of wear & tear

applications:

fertilizers

dyestuffs

chemical products

insecticides & pesticides

mineral

pigments colors

metal separation

spices

refractory

ceramics

dolomite

lime stone

coal