Listing ID #3991369

Company Information

Ask for more detail from the seller

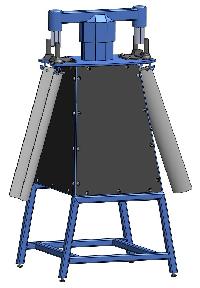

Contact Supplier| D.P. Pulverisers manufacture a large variety of Impact Crushers to virtually any size reduction job. The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run. The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty required. We can provide a Impact Crusher to reduce almost any material to the size required. |

| Operating Principle of Impact Crusher |

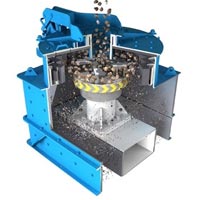

| Material is fed in Impact Crusher from the periphery through a hopper into the grinding chamber to minimize air pressure, greatly reducing dust problems. For some material suitable ventilation is recommended by introducing air on the discharge side of the crusher, this will prevent a dusty atmosphere at the inlet of Impact Crusher. The swinging hammers in Impact Crushers crush the materials along the stationery liners before discharging through a perforated screen at the bottom; replaceable bar type screen is available for specific application. Combination of hammer style, liner plates and sieve inserts offer almost unlimited possibilities to cater user needs from an Impact Crusher. |

| Applications of Impact Crusher |

| The Impact Crushers are used for crushing or shredding of diverse materials such as: Limestone, Glass, Coal and Lignite, Clay, Sand, Phosphate, Rock, Fertilizer, Aluminium Oxide, Slags, Coke, Silica, Bauxite, Dolomite, Grain, Barytes, etc. |

| Outstanding Features of Impact Crusher |

|

| Model | H.P | R.P.M. | Grinding Chamber | Max FeedSize (mm) | |

| Dia (mm) | Width (mm) | ||||

| D.P.I.C. - 10 D.P.I.C. - 20 D.P.I.C. - 30 D.P.I.C. - 40 D.P.I.C. - 50 D.P.I.C. - 60 D.P.I.C. - 70 D.P.I.C. - 80 |

7.5 10 15 25 50 60 80 100 |

4000 4000 3000 3000 2500 2500 2000 2000 |

275 275 375 375 600 600 750 750 |

150 200 200 300 300 400 400 500 |

25 30 50 50 75 75 100 100 |