Listing ID #2068328

Company Information

Ask for more detail from the seller

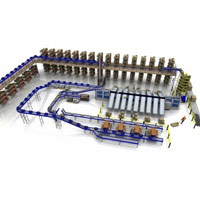

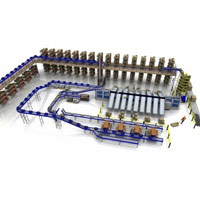

Contact SupplierIdler roller is a important spare of a belt conveyor as it directly affects performance of conveyor. What is an Idler Roller

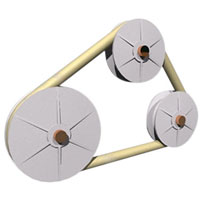

Idler Rollers are used in belt conveyor systems for supporting belt in between the two Pulleys i.e. Drive Pulley and Tail Pulley. Idlers can be divided in following 3 types

Carrying Rollers These are the rollers which support upper side of the conveyor i.e. Carrying Side where the material is carried over belt. Motion of the belt is from Tail Pulley to Drive Pulley.

Return Rollers These are the rollers which Support Bottom side of the conveyor i.e. return Side where belt returns to the drive pulley. Motion of the belt is from Drive Pulley to Tail Pulley.

Impact Rollers These are the Rubberized carrying rollers installed where the material is feed on the belt. Rubber rings are attached over the rollers to avoid damage of rollers and belt due to Impact of feeding material at feeding point.

Each Idler manufactured requires following raw material

Pipe 1 No (As per Face Width of idler)

Spindle Shaft 1 No (As per Length of Spindle)

Bearing Housings 2 No (As per bearing Size)

Set of Five Seals 2 No (As per bearing Size)

Bearings 2 No (As per Requirement of customers)

Rubber rings as per requirement of customer for impact idlers only

Manufacturing Process of Roltech Idlers

Since Process quality deliver product just in time at economical cost we manufacture idlers as per following process.

Pipe: We use electric resistance welded (ERW) pipe of right quality cut to size and both ends maintaining co – axiality of bores.

Shaft/Spindle: Shaft is made up of M.S. polish bar cut to size & machined between centre to achieve perfect fitment between shaft & bearing.

Bearing Housing: At Roltech we use pressed steel housing made from a ductile steel plate and weld these housing on both side of pipes with using a special purpose welding machine to achieve excellent quality of weld. As per customer requirement aluminum or CI bearing housing can be used.

Sealing: Five stage sealing is used to seal bearings which include back seal inner & outer, labyrinth seal dust cover & rain protective cap. This assures water proof & dust proof idler.

Assembly: The accurately machined parts after quality testing are accepted & assembled in separate assembly area to assure dust free atmosphere.