Listing ID #3847274

Company Information

Ask for more detail from the seller

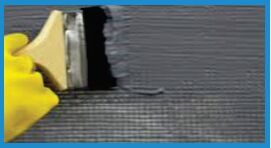

Contact Supplier“IC PRECISEAL” is single component, polymer modified, elastomeric waterproofing coating for concrete and masonry surfaces. It is a single component and only water is to be added during mixing at site. The product can withstand water impermeability against hydrostatic pressure to counter positive as well as negative side water pressure ingress.

The product can be easily applied by brushing or by spray equipment for larger areas. It has a very high tensile adhesion strength, crack bridging capability and is UV resistant. It can be applied both on the exterior and interior surfaces.

“IC PRECISEAL” complies with the guideline given in EN 14891, ASTM D5385, EN 1348 and DIN 1048.