Listing ID #1684529

Company Information

Ask for more detail from the seller

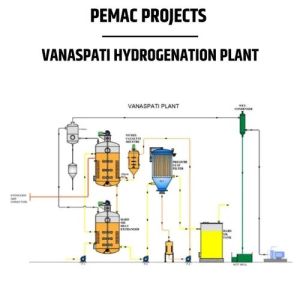

Contact SupplierHydrogenation is the process to change the physical characteristics of natural fats and oils.

Hydrogenation of vegetable oils involves the addition of hydrogen, in the presence of a Nickel catalyst, to the carbon-carbon double bonds present in the fatty acid chains.

Salient features:

Interesterification

Interesterification can be defined as a redistribution of the fatty acid moieties present in a triglyceride oil over its glycerol moieties. Interesterification has become the alternative fat modification technology to partial HYDROGENATION.

Interstification is the process of re-arranging the fatty esters within and between tri-glycerides resulting in the most cases a change in the physical properties of the oil / fats. Interstification is the intra and inter molecular exchange of fatty acids on the glycerol back bone of tri glycerides. In the chemical Interstification process commonly used catalysts are sodium methylate and ethylate followed by sodium methoxide.

In enzymatic Interstification process, the enzyme commonly used is lipozyme TL1M.