Listing ID #3483239

Company Information

Ask for more detail from the seller

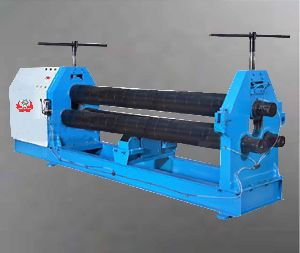

Contact SupplierThe main advantage is that the plate can be feed horizontally since the bottom and one pressure roll work as a support roll for plate ( in case of 3 roll machine plate is required to feed in a slant position)Also the pressure roller on opposite side works as a reference surface and plate can be fed at perfect right angle to pressure roll or machine. After the plate is held firmly between top roll and pinching roll , the pressure roll advances to form desired radius on plate edge and adjacent area as shown The radius thus formed is checked with the template and same procedure is repeated till the template matches with pre bentpre pinched edge of plate. After pre pinching the one edge of plate the same procedure is repeated on the another edge of plate to form pre pinching radius. After forming desired radius on both the edges ,the rollingbending is carried our by rotating all rolls in a reverse and forward direction till the complete circle is formed. It is possible to form different shapes like square, rectangle, polycentric, elliptical,etc shapes more precisely ,but it is must that this are formed in a single pass and machine with PLC based controls is most suitable for this application. Also this machine is most suitable for mass production type components which requires repeatedly same output results mass. For engineering shop where same size of rolled products are required to be produced in small quantity and the sizes may change on day to day basis depending on job type ,the shell can be produced by rolling completed in multiple pass.